We transport our dogs in boxes on our dog truck (a

Toyota Tundra). Transporting the rigs and sleds is

another story.

We modified our three wheeled Fritz Dyck SAM rig

to allow the uprights to easily fold flat. With the

SAM, a large cotter pin is used to connect and disconnect

the steering shaft. We replaced the standard metric

allen screws and nyloc nuts attaching the upper side

supports with universal clevis pins and hairpin cotter

pins.

The four wheeled Fritz Dyck TOM rig is a good bit

larger than the SAM and more difficult to transport.

In particular, the TOM rig does not have a split steering

shaft and requires disconnecting multiple metric rod

ends to collapse the rig to fit in our vehicle. In

this case, it did not seem practical to change to

a quick release system.

We decided to go with a hitch mounted carrier. Most

hitch mounted cargo carriers and mobility carriers

are not large enough to carry a larger rig. VersaHauler

makes an ATV (VH90)

carrier suitable for large ATV's and rigs. VersaHauler

rates the maximum ATV weight based on the size and

configuration of the carrier vehicle. Typically, you

need a 3/4 ton truck to have the suspension capacity

required for a VersaHauler.

We decided to make our own hitch mounted carrier

based on dimensions from Sled

Dog Central.

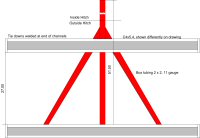

The plan drawing is shown below. Click on the image

for an enlarged version. Please note that the following

drawing has not been reviewed for structural calculations.

We used 11 gauge 2 in. x 2 in. box tubing for the

main and diagonal supports. One 20 foot length provided

sufficient material for all three components.

We used C4x4.5 for the wheel tracks. Initially, we

planned on building the channels from expanded metal

(for the floor) with an angle iron frame. The C4 channels

were a bit cheaper than the angle and expanded metal.

The TOM has a different front and rear track, which

makes the process a bit harder. The C4 channels are

basically the same width as the TOM tires. Our initial

version of the hitch carrier had the rear channel

(furthest from the vehicle) welded in place and the

front channel bolted on. Because the front and rear

tracks do not match, the front channel and rear channel

are not parallel. If we were to do it again, we would

make wider channels for both, which would allow the

channels to be parallel and make it easier to load.

Since we have both the three wheel SAM and four wheel

TOM rigs, the rear channel was welded to the frame.

The front channel can be moved to adjust between the

two rigs. A third channel is bolted to the frame for

the center wheel of the SAM rig.

After using the hitch carrier several times, we decided

to modify the design. Our initial carrier had a longer

main support (approximately 51"), which gave

the cart roughly 8" to 10" of clearance

from the rear bumper. The design also acted as a giant

lever and the weight of the rig tended to cause a

fair amount of motion at highway speeds. As a result,

we moved both channels in towards the vehicle and

cut off the excess material at the rear of the carrier.

In the process, we changed from a welded rear channel

and bolted front channel to a welded front channel

and bolted rear channel. In addition, stiffeners were

added to reduce rotation. The net result was to move

the rig in towards the center of gravity of the vehicle.

This appears to have helped to some degree.

We created tie down attachment points on each channel.

We took a scrap of box tubing and cut it into 1/4

in. long sections. The sections were welded to the

outside edges of the channel and provide secure locations

for ratchet tie downs. We found that standard ratchet

tie downs can release and replaced the tie down hooks

with clips with gates.

The rig carrier was originally built for our old truck, a 1998 Ford Expedition. Years later, the rig

carrier is still in service with an occasional coat

of fresh paint.

|